News Center

Dual-Channel Hairpin Winding Machine: Efficient Flat Wire Motor Production

Published on.

2025-06-05 17:09

Source

As the electric vehicle industry accelerates, hairpin motor are emerging as a key component in drive systems due to their high power density and low energy loss. Market demand is soaring, but traditional winding equipment struggles to keep pace. Limited production efficiency, lack of versatility, and poor adaptability have become major bottlenecks, restricting manufacturers from scaling up and meeting evolving production needs.

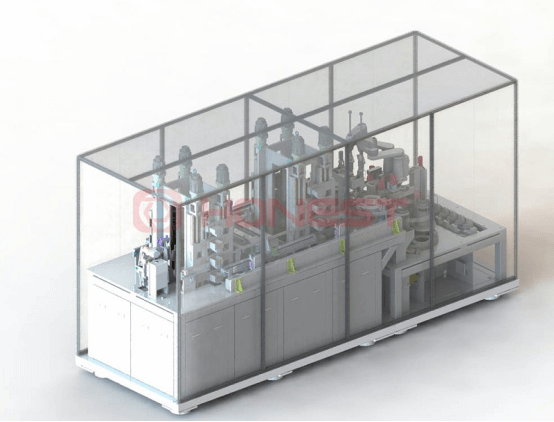

HONEST Automation has recently launched a next-generation dual-channel hairpin winding machine, setting a new industry benchmark. With its innovative design and exceptional performance, this breakthrough solution redefines traditional winding equipment and brings new momentum to efficient, intelligent flat wire motor production.

The standout feature of this dual-channel hairpin winding machine lies in its unique dual-channel design. Two independent working channels operate simultaneously, enabling seamless coordination from wire forming to processing. This dramatically shortens the production cycle. Compared to single-channel models, this machine delivers an impressive output of up to 3,000 flat wires per hour at a forming speed of 1.25 wires per channel, setting a new benchmark in efficiency and outperforming similar products in the market.

Moreover, the machine is equipped with an optional automatic wire cup insertion function, which can be activated based on specific production requirements. This automated system ensures precise and rapid wire insertion, significantly reducing manual labor intensity and error rates. It also streamlines the transition between processes, making the production flow smoother and more efficient, while boosting overall productivity.

Key innovations of this machine include:

Versatile Functionality: Flexible Configurations for Diverse Production Needs

This machine supports a wide range of mold combinations, including 2D, 3D, and integrated mold options, making it adaptable to various winding structure types. Its innovative 2D+3D mold tower design allows for rapid tool changes, dramatically reducing changeover time. Even in multi-variety, small-batch production environments, it maintains high efficiency and maximizes equipment utilization.

Wide Compatibility: Expanded Application Across Industries

The equipment is compatible with various pin types, including H-pin, X-pin, and MIN-pin, enabling flexible deployment across multiple sectors such as electric vehicles, industrial motors, and household appliances. It meets diverse manufacturing requirements and helps businesses easily expand their product offerings and markets.

Space Optimization: Compact Footprint for Efficient Floor Utilization

While delivering high performance, the machine also features a space-saving design with a footprint ranging from just 1.8 to 9 square meters, up to 30% smaller than comparable models. This compact layout is ideal for facilities with limited space, helping reduce infrastructure costs and allowing manufacturers to allocate more resources to core production and R&D.

In conclusion, the dual-channel hairpin winding machine developed by HONEST Automation stands out with its exceptional advantages in production efficiency, functional flexibility, space utilization, and automation. It not only delivers a smarter and more efficient manufacturing experience for enterprises but also helps customers gain a competitive edge while accelerating technological advancement across the industry.

If you are looking for a high-performance hairpin motor production solution, we warmly invite you to visit the HONEST factory. Engage with our technical engineers, explore the machine in action, and discover how this innovative equipment can enhance your productivity and strengthen your market position.

Next page

Related News