News Center

Top 5 Quality Control Tips to Prevent Hairpin Motor Failures

Published on.

2025-06-11 17:29

Source

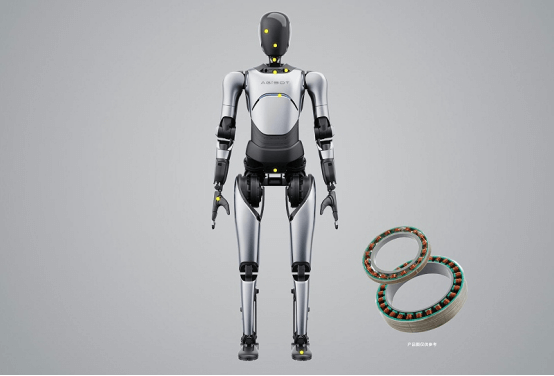

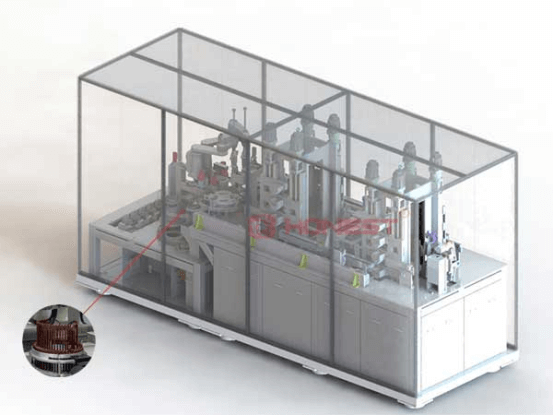

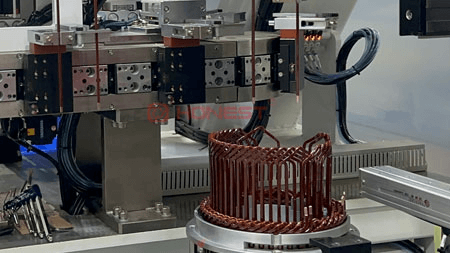

With the development of electric vehicles and high-efficiency industrial motors, hairpin motors have gradually become the mainstream trend in the electric vehicle motor industry due to their unique advantages. The previous article provided a detailed introduction to the dual-channel hairpin motor stator winding machine. As the core equipment for hairpin motor stator production, the quality of its output directly determines the performance and reliability of the motor.

In an increasingly competitive market, ensuring the production of high-precision, high-quality stator windings through effective quality control has become a top concern for motor manufacturers. This article explores the specific quality control measures implemented during the actual production process of the dual-channel hairpin motor stator winding machine.

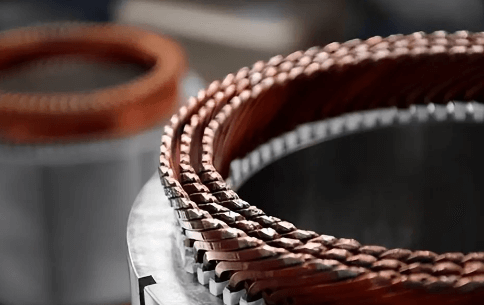

As the core conductive material for stator windings, hairpin copper wire must undergo strict material inspection. Manufacturers are required to test the copper content rigorously and precisely measure key properties such as resistivity and hardness to ensure all parameters meet the specific requirements of motor production. Additionally, surface quality must be carefully checked—any scratches, cracks, or surface defects may lead to localized electric field concentrations during motor operation, potentially compromising the insulation performance of the stator windings and even causing short-circuit failures.

For insulation strength testing, it is essential to simulate the voltage conditions experienced during actual motor operation and conduct dielectric withstand (hi-pot) tests on the insulation materials. This ensures they can endure prolonged exposure to high voltage without breakdown. Additionally, since motors generate substantial heat during operation, it is critical to monitor the performance of insulation materials under varying temperatures and durations to prevent premature aging that could shorten motor lifespan. Furthermore, specialized adhesion tests must be carried out to ensure the insulation layer is firmly bonded to the hairpin conductors.

Mold Precision Management: High-precision measuring instruments should be used regularly to detect dimensional deviations during mold usage, allowing for timely repair or replacement. To meet future diversified production demands, it is also advisable to prepare multiple sets of 3D molds and fully use the winding machine's automatic mold-changing function, enabling fast and efficient product switching.

Cutter System Management: For tool selection and replacement, the system should automatically choose the appropriate cutter from the tool library based on the shape of the wire ends and specific process requirements. A comprehensive tool life management system should also be established, utilizing sensors to monitor real-time data such as usage count and wear level. When a cutter reaches its predefined lifespan or exceeds the wear threshold, the system will automatically issue a replacement alert. This prevents issues such as uneven cuts or burrs caused by worn tools, ensuring cutting precision and product quality.

Cutter System Management: In terms of tool selection and replacement, the system should automatically select the appropriate cutter from the tool library based on the shape of the wire ends and specific process requirements. A robust tool life management system must also be implemented, using sensors to continuously monitor key parameters such as tool usage count and wear level. When a cutter reaches its preset lifespan or the wear exceeds a defined threshold, the system will automatically trigger a replacement alert. This helps prevent issues like uneven cuts or burrs caused by worn tools, ensuring consistent cutting quality and process stability.

Ensuring Equipment Stability: For example, regularly lubricating components of the transmission system, such as bearings and gears, can effectively reduce friction and wear, thereby extending the equipment’s service life. Additionally, routine inspections of electrical components are essential to ensure there are no faults or poor connections. This helps prevent unexpected electrical failures that could disrupt production or lead to inconsistent product quality.

Quality control in the actual production of dual-channel hairpin motor stator winding machines involves a comprehensive and systematic approach. By implementing targeted quality control measures, such as strict material inspection of hairpin copper wire, evaluation of insulation materials, precision maintenance of molds, cutter system management, and ensuring equipment stability, manufacturers can significantly enhance the production quality of hairpin motor stators. This ensures that the final products meet the growing market demand for high-performance, high-reliability motor stators.

Looking ahead to the future of industrial manufacturing, as technology continues to advance and market demands become increasingly diverse, motor manufacturers must remain focused on the innovation and application of quality control technologies. By continuously improving their quality control systems, they can lay a solid foundation for the high-quality development of the hairpin motor industry.

Related News