News Center

How Rotor Winding Machines Power Both Brushed and Brushless Motor Production?

Published on.

2025-08-13 11:43

Source

With the rapid growth of industrial automation and the new energy vehicle industry, the demand for motors—widely recognized as the core power components in modern technology—continues to increase. In motor manufacturing, brushed motors remain popular in small appliances and power tools due to their simple structure, low cost, and ease of control. On the other hand, brushless motors are becoming the preferred choice in high-end applications, offering higher efficiency, longer lifespan, and quieter operation, making them essential in advanced automation systems and electric vehicles.

Against this backdrop, many customers face a common challenge in motor design: a single motor product often needs to be offered in both brushed and brushless versions to meet the requirements of different markets and application scenarios. This raises a key manufacturing question that motor manufacturers frequently bring up: Can brushed motor rotors and brushless motor rotors be produced on the same rotor winding and assembly line?

In this article, we will explore this question by examining the structural differences, process characteristics, and technical challenges involved. The goal is to provide practical insights for motor manufacturing companies as they address the growing demand for diversified, small-batch, and multi-model production.

1. Structural Differences

To evaluate the feasibility of integrated production, it is essential to first understand the fundamental structural differences between brushed motor rotors and brushless motor rotors.

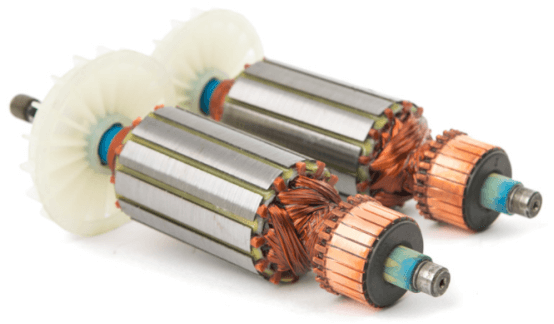

Brushed Motor Rotor: The core component is a wound rotor, typically consisting of a laminated iron core, copper windings, and a commutator. The commutator works in conjunction with carbon brushes to reverse current flow, enabling the rotor to maintain continuous rotation.

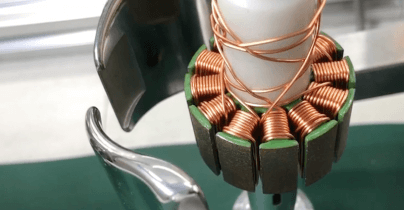

Brushless Motor Rotor: The core component is a permanent magnet rotor, usually formed by bonding or embedding magnetic materials onto the rotor core to create a constant magnetic field. Unlike its brushed counterpart, the brushless rotor does not have windings or a commutator. Instead, it relies on an external electronic controller to precisely regulate the stator winding currents and achieve rotation.

2. Manufacturing Process Differences

The core manufacturing process of a brushed motor rotor lies in winding plus commutator welding, while that of a brushless motor rotor centers on magnet assembly and magnetization. These processes not only require highly specialized equipment but also differ significantly in terms of environmental conditions, material handling, and cycle time control, making them difficult to integrate on the same production line.

3. Challenges of Integrated Production: Not Just a Simple “Switch”

Given the process differences described above, achieving true integrated production presents significant challenges. The main issue lies in the following:

High equipment specialization and process incompatibility: The manufacturing of brushed motor rotors and brushless motor rotors depends entirely on different types of dedicated equipment. On a single production line, it is extremely difficult to efficiently perform two fundamentally different core processes at the same time.

Long Changeover Time: Even on the same physical production line, switching from a brushed motor rotor to a brushless motor rotor requires replacing numerous fixtures, adjusting equipment parameters, and sometimes even swapping key equipment modules. This changeover process is time-consuming and labor-intensive, significantly reducing production efficiency.

Quality Control Risks: The differing environmental and material requirements of the two processes make mixed-line production prone to cross-contamination and quality issues, increasing overall manufacturing risk.

Therefore, achieving true seamless production of both brushed and brushless motor rotors using a single set of equipment is not realistic under current technological conditions. Motor manufacturing does not have a “one-size-fits-all” template; even minor differences in dimensions or assembly sequence can render standardized equipment incompatible.

In summary, while integrated production may sound like a cost-saving and efficient solution, the reality of technology and manufacturing practice shows that the production of brushed motor rotors and brushless motor rotors still requires either separate or highly modular production lines. Forced integration may fail to reduce costs and could even decrease overall production efficiency while introducing quality risks.

Nevertheless, this does not mean that companies cannot meet diversified production demands. By combining modular line design, flexible tooling, rapid changeover techniques, and intelligent scheduling systems, manufacturers can still build highly flexible production systems capable of small-batch, multi-model, and high-efficiency rotor production switches. (Specific solutions can be adjusted according to individual manufacturer capabilities.)

If you are facing challenges in the production of brushed or brushless motor rotors, feel free to leave a message online to receive customized solutions and a tailored quote from our technical team specializing in stator and rotor manufacturing.

Related News