News Center

Why Automated Equipment Is the Optimal Choice for Hairpin Motor Winding?

Published on.

2025-08-19 14:16

Source

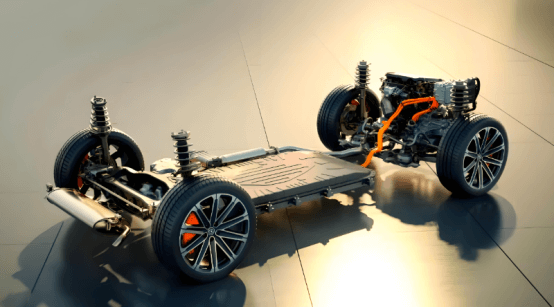

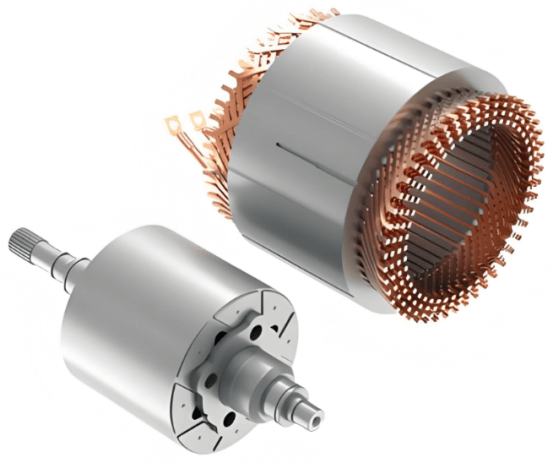

With the rapid development of high-performance drive systems in electric vehicles and industrial motors, hairpin motors have emerged as a key technology upgrade path due to their high power density, energy efficiency, and excellent thermal performance. As a critical manufacturing step, the quality of the winding formation directly determines the electrical performance, mechanical stability, and long-term reliability of the motor. Among various winding types, H-pin winding is widely adopted in high-end hairpin motor production for its compact design and low copper loss advantages.

However, even in the era of Industry 4.0 and smart manufacturing, some companies still rely on traditional manual twisting during the hairpin motor winding process. This approach not only contradicts the trends of automation and digitalization but also presents several practical challenges, such as:

Inconsistent precision: Manual operations are affected by individual skill levels and fatigue, making it difficult to ensure uniformity for each winding, which can lead to performance fluctuations.

Low production efficiency: The slow pace of manual work cannot meet the demands of high-volume, high-throughput production.

Poor quality stability: Issues such as winding angle deviation, stress concentration, and insulation damage are common, increasing the risk of motor failure.

High labor cost and difficult management: Production heavily relies on skilled operators, with long training cycles, and workforce turnover can disrupt production line stability.

In modern factories pursuing “zero-defect” manufacturing and lean production, manual twisting has become a bottleneck that limits the quality improvement and capacity expansion of hairpin motors.

To address the challenges in hairpin motor winding, automated hairpin motor production equipment has become the industry standard. These machines integrate high-precision servo control, visual positioning, and flexible clamping technologies, allowing pre-formed flat copper wires to be accurately fed into molds via robotic arms or conveyor systems. Meanwhile, cut-free twisting equipment, with precisely designed independent twisting heads and optimized mold structures, eliminates the need for flattening processes. By sharing dual-axis data across every two winding layers, it accommodates any number of slots and layers, ensuring naturally flat wire ends after twisting.

Compared to manual operations, automated hairpin motor production equipment offers significant advantages:

High consistency: Ensures uniform winding parameters across all motors, improving product reliability.

Increased efficiency: A single machine can replace multiple operators, significantly reducing production cycle time.

Reduced scrap rate: Minimizes human errors, preventing rework or defects caused by improper winding.

Strong traceability: Supports data collection and integration with MES systems, meeting Industry 4.0 standards.

If you are seeking a high-efficiency, stable, and intelligent solution for hairpin motor stator winding, Honest Automation is your trusted partner.

As a high-tech company specializing in intelligent motor manufacturing equipment, we offer a complete range of automated solutions, including flat wire insertion, twisting, welding, and testing, enabling customers to transition from manual to smart manufacturing.

Welcome to connect with our technical team for solutions. Together, let’s drive continuous advancement in hairpin motor manufacturing in the era of smart manufacturing.

Related News