News Center

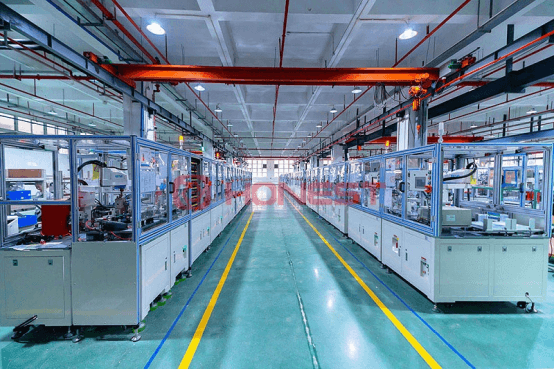

Motor Production Line: The Key to Operator-Free Manufacturing

Published on.

2025-08-28 17:11

Source

In today’s manufacturing transformation, lights-out production has become a key strategy for motor manufacturers to overcome bottlenecks and enhance efficiency. Rising labor costs and a shortage of skilled workers make traditional manual production increasingly unsustainable. At the same time, the global wave of Industry 4.0 and smart manufacturing is accelerating the shift toward more efficient, intelligent, and precise automated production.

Against this backdrop, motor automation equipment has emerged as the driving force behind intelligent manufacturing. Serving as the “power core” of production, it lays the foundation for factories to move from stand-alone automation to fully integrated production lines. Its role is indispensable in enabling lights-out production.

The foundation of lights-out production lies in the precise drive and intelligent control provided by the motor production line.

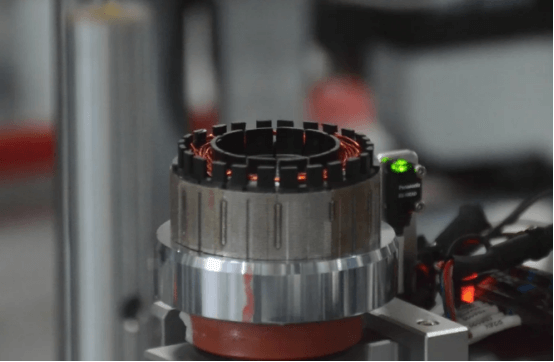

First, motors deliver the fundamental power for automated production. Servo motors and stepper motors excel in precision control, enabling highly accurate operations such as material handling, assembly, and machining.

In addition, the integration of motors with sensors and controllers allows real-time data feedback and automatic parameter adjustments, significantly reducing the need for manual intervention and making production more intelligent and reliable.

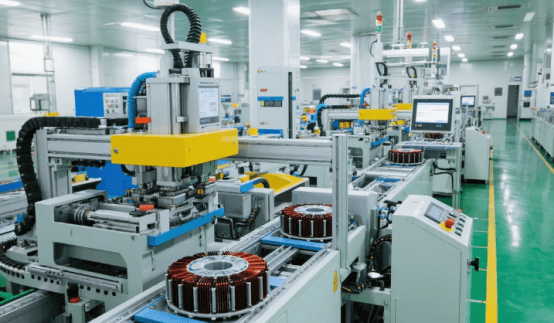

The impact of motor assembly equipment on lights-out production is particularly evident.

From the perspective of efficiency, these systems can operate continuously, 24/7, with stable performance, thereby eliminating the time and efficiency constraints associated with manual labor. Moreover, their precise control minimizes material waste and significantly shortens production cycles.

In terms of product quality, motor-driven equipment achieves millimeter-level precision, effectively eliminating errors that can occur with manual operation. During production, key parameters can be automatically recorded and stored, enabling data-driven traceability and supporting standardized quality management.

From a cost and operational perspective, motor assembly equipment significantly reduces the need for manual labor, lowering both staffing and training costs. Through intelligent energy management, it also minimizes energy consumption and extends equipment lifespan. Furthermore, in high-risk environments such as chemical processing or high-temperature operations, these systems replace human operators, greatly enhancing production safety.

In practice, various industries have successfully leveraged motor production lines to achieve lights-out production. For instance, in automotive motor manufacturing, motor-driven welding robots can perform component welding with high precision and energy efficiency. When combined with AGV material handling systems, materials can be transported automatically, enabling fully automated production lines that significantly improve both productivity and product quality.

However, implementing lights-out production also presents certain challenges. The initial investment cost can be substantial for many companies. Technical compatibility is another key consideration, as motors and automation equipment from different brands or models may not seamlessly integrate with existing production systems, potentially affecting workflow efficiency. Additionally, equipment maintenance requires skilled technicians; complex malfunctions that are not promptly addressed could result in production interruptions.

In the face of rapidly changing market demands and industry challenges, Honest Automation has leveraged years of expertise in motor assembly line to provide strong support for companies pursuing lights-out production. With extensive experience in cost management, enhanced equipment compatibility, and professional maintenance services, we help ensure a smooth transition to fully automated manufacturing.

If you are looking for high-performance and highly compatible motor production line, please leave a message online or email our technical experts for a customized solution and quote.

Related News