News Center

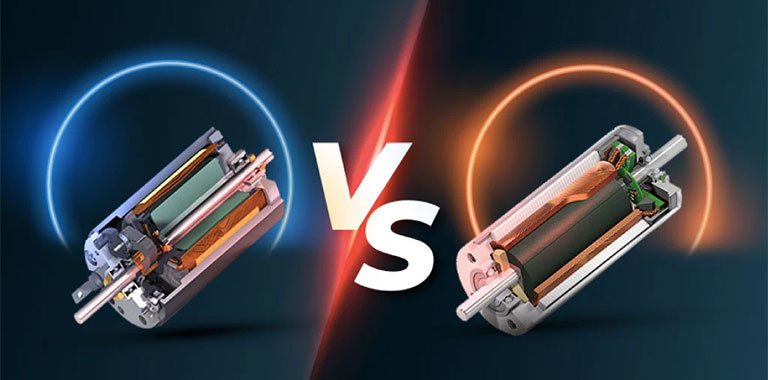

BLDC Motor vs Brushed Motor, and the Introduction of Motor Winding Equipment

Published on.

2024-11-09 11:11

Source

BLDC motor and brushed motor are two common types of motors, widely used in various fields. Their function is to convert electrical energy into mechanical energy to power various equipments. They each have their own characteristics and are suitable for different working scenarios.

The Structural Difference Between BLDC Motor and Brushed Motor

Brushless motor: Using electronic commutation technology, the motor rotor is usually made of permanent magnet material, and the stator has multi-pole windings. This structure makes the brushless motor perform well in terms of efficiency and energy consumption, with higher efficiency and lower energy consumption.

Brushed motor: It contains a brush device inside, which is mainly composed of carbon brushes, commutator and other parts. The carbon brushes are the two contacts of the motor power supply, which contact and rub with the commutator to introduce or extract voltage and current. The rotor of the brushed motor has windings, which form a magnetic field after power is applied, interacting with the magnetic poles on the stator to generate torque and make the motor rotate.

The Difference in Performance Between Brushless Motor and Brushed Motor

Brushless motor: Without brushes, energy loss and heat generation are reduced, so it has higher efficiency and lower energy consumption. At the same time, brushless motors use electronic commutation technology, which can achieve higher speeds and smaller torque fluctuations, and the noise and vibration are relatively low.

Brushed motor: It has the characteristics of fast starting and timely braking, can smoothly adjust the speed in a wide range, and the control circuit is relatively simple. Due to the contact friction between the brush and the commutator, the brushed motor will generate greater noise and vibration during operation.

However, the performance of brushed motor and brushless motor directly affects the efficiency and reliability of the motor, and sophisticated automated assembly is essential for the performance requirements of brushed motor and brushless motor. As a supplier of motor intelligent equipment solutions, HONEST has extensive experience in the assembly of brushed motor and brushless motor.

Considerations for Designing Motor Assembly Line

Motor assembly line design: In order to ensure that the brushed motor and brushless motor production lines can be assembled accurately, Hollis uses professional automated assembly equipment to ensure that each component can operate efficiently and stably, reduce human operating errors, and improve production efficiency. At the same time, the cooperation between the clamp and the belt line ensures stability and safety during the transmission process.

Precise component calibration: Before assembly, all incoming motor parts are precisely calibrated using high-precision measuring equipment and technology to ensure that the size and shape of each component meets the design requirements.

Precision assembly: High-precision assembly settings are used to ensure that key components such as stator windings, rotor magnets and electronic commutators can be accurately matched, thereby ensuring the overall performance and life of the motor.

Visual inspection system: Using high-precision visual inspection system and image processing technology, each step of the assembly process is monitored in real time. This system can quickly detect deviations or errors in the assembly process so that they can be corrected in time to ensure the correct placement of components.

Comprehensive test: After assembly, a comprehensive performance test is carried out, including the detection of efficiency, speed, temperature and other parameters to ensure that the motor meets the design requirements.

Leading Supplier of Motor Winding Equipment

As a supplier of motor winding equipment, Shenzhen HONEST is well aware of the key role of brushed motor and brushless motor in different applications. We are committed to providing digital and intelligent motor equipment solutions for new energy vehicles, automotive electric parts, rail transportation, aviation, home appliances, industry, robotics at home and abroad. This can not only meet the strict requirements of different customers for motor performance, but also provide non-standard customized services to meet the ever-changing market needs, help customers improve product production efficiency, reduce maintenance costs, and achieve better performance.

Related News