News Center

How to Control the Main Drive Motor Automatic Production Line Through Programming?

Published on.

2023-07-29 14:45

Source

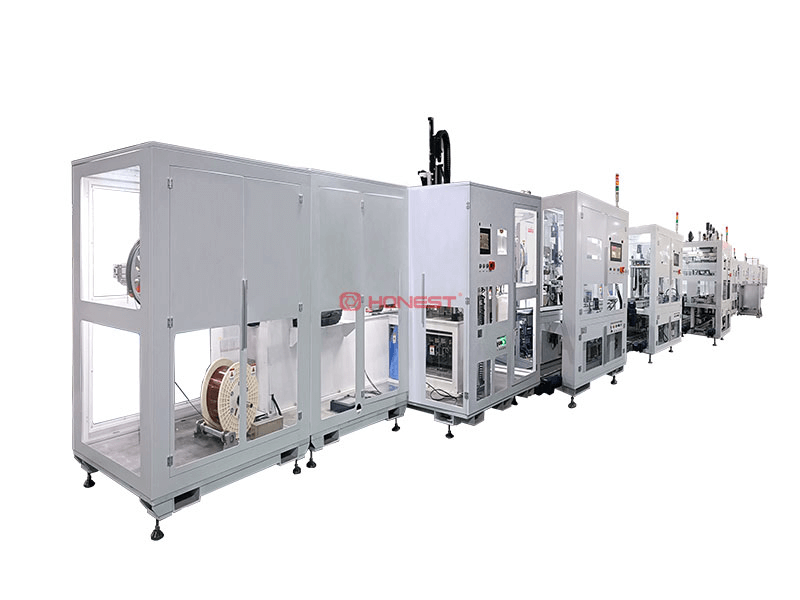

The automatic production line of the main drive motor is a very important task in the modern manufacturing industry. In order to achieve this goal, many manufacturers have adopted a programming method to control and manage the automatic production line of the main drive motor. HONEST will introduce how to control the automatic production line of the main drive motor through programming.

1. The Basic Principles of the Main Drive Motor Automatic Production Line Control.

The automatic production line system of the main drive motor refers to the operation of the automatic production line through programming to control the start, stop, speed adjustment and other operations of the main drive motor. Before starting programming, we need to understand the working principle and control requirements of the main drive motor so that we can design a suitable control scheme.

2. Choose the Right Programming Language and Platform.

The programming language is the basis for realizing the automatic production line control of the main drive motor. Common choices include C/C++, Python, PLC programming, etc. For beginners or non-professionals, Python is an easy-to-learn and powerful programming language suitable for rapid prototyping and implementation of control logic.

3. Design control logic and algorithms.

In the programming process, it is necessary to design the control logic and algorithm of the main drive motor to achieve the expected function, which may include speed adjustment, timing start and stop, position control, etc., and methods such as PID control algorithm and state machine can be used to realize the control logic.

4. Communicate with the main drive motor.

In order to realize the control of the main drive motor, we need to establish communication with it. This can be achieved through communication protocols such as serial ports, Ethernet, Modbus, etc. During the programming process, it is necessary to write corresponding codes to establish communication connections and send control commands to the main drive motor.

5. Testing and debugging.

After writing the control code, it needs to be tested and debugged to ensure the normal operation of the automatic control function of the main drive motor. By simulating actual working scenarios and different control situations, verify the accuracy and stability of the control logic, and make necessary adjustments and optimizations.

6. Deploy and monitor.

Once the main drive motor automatic production line control scheme is tested and debugged, it can be deployed into the actual production environment. After deployment, monitoring and maintenance are required to ensure the stability and reliability of the control system. By monitoring the operating status of the control system, data collection and analysis, problems can be found and solved in time to improve production efficiency and quality.

Finally, the automatic production line control of the main drive motor can be realized through programming, which can improve the production efficiency of the enterprise, reduce costs, reduce human errors, and create more opportunities for the development of the enterprise. Whether in industry or everyday life, the wonders of programming are changing our world, leading us to a smarter and more automated future.

Related News