News Center

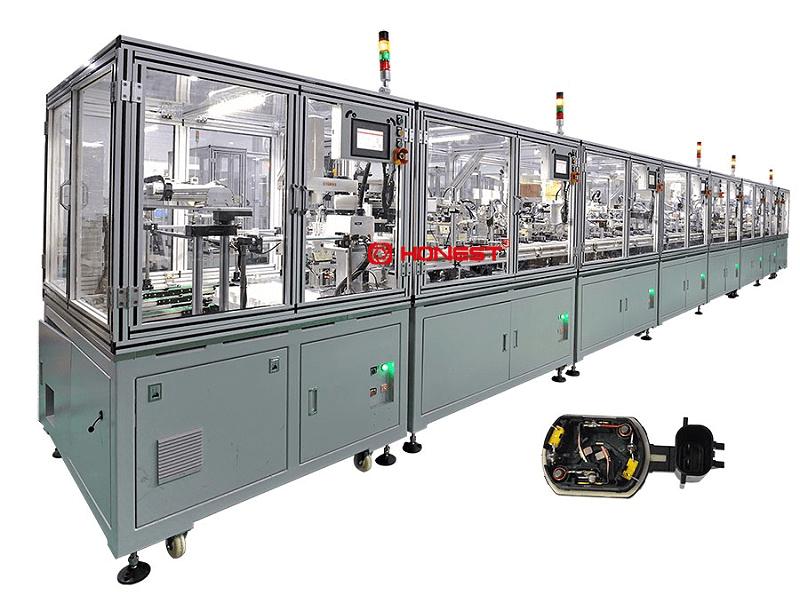

Motor end Cap Assembly Line Installation & Commissioning Completed

Published on.

2021-01-19 14:23

Source

Motor end cap assembly equipment is used the field of automotive door and window motors. Its main processes include plastic cover feeding, bearing assembly, brush arm assembly, terminal riveting, capacitor assembly, thermal protector clamp welding, inductance and Brush arm clamp welding, clamp welding inspection, varistor clamp welding, resistance test, NG rejection, good product blanking, etc. The equipment efficiency reaches 600pcs/h, the yield rate of the whole line reaches 98%, and it is compatible with 32 products. It has a one-key changeover function and the changeover time is only 10 minutes. Its small shell loading and unloading is designed as standard loading and unloading equipment, which can be used in the production of various sizes of products. The changeover only needs to adjust the belt width. The whole line equipment has a simple and compact structure, and the jig is moved quickly by a servo screw. Transplanting can be modularized and assembled freely, and N fixtures can be transferred simultaneously. After the unqualified product is generated, the abnormal position can be quickly traced, and the functional equipment can be quickly disassembled and assembled. The whole line only needs 2 people to operate, and the control method is PLC+touch screen, which can save more labor cost.

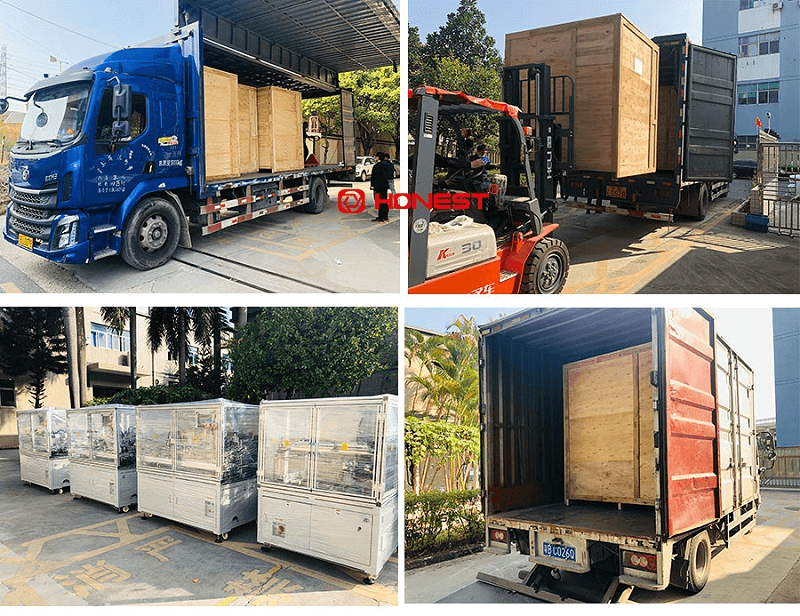

After the production line arrives at the customer's factory, our engineers will also go to the factory to install and debug the equipment, and provide a full range of one-to-one operation guidance and technical training. Our technicians to stay in the customer's factory for a long time, we can quickly provide solutions when customers have problems using the equipment production line. HONEST focuses on the R&D and customized production of motor automation equipment. And more than 13 years of R&D experience in the motor production line. Our leader has 27 years of experience in the motor industry. He is very familiar with motor performance and related process requirements and technologies. Therefore, we can provide customers with solutions in a short time.

If you are looking for motor winding equipment or motor assembly line, please feel free to contact us so we can help you to make the right choices.

Related News