News Center

The development trend of new energy vehicle motors: the replacement of flat wire (hairpin wire) motors for round wires is accelerating

Published on.

2022-07-15 11:04

Source

According to the current development trend of new energy vehicles, the placement of flat wires for round wires is accelerating. Compared with the traditional round wire motor, the flat wire (hairpin wire) motor owns a great advantage above it. At present, new energy vehicles are in a period of rapid development, product quality is rapidly improving, and consumers have higher and higher requirements for performance. Flat wire motor is a winding technology with complicated manufacturing process and currently has a high technical premium. The so-called flat wire motor refers to the change in the shape and structure of the wires used in the stator winding design, from multiple thin round wires to thick rectangular wires, commonly known as flat wires.

The advantage of flat wire motor

1. High-efficiency conversion of flat-wire motors saves battery costs. Flat wire motors can greatly improve conversion efficiency and reduce battery costs. The cost savings of 1,000 yuan per vehicle is of great significance to car companies. Under the circumstance that the cost of new energy vehicles and power batteries is still too high, how to reduce costs is the eternal pursuit of car companies, and how to improve the efficiency of motors is one of the effective ways to reduce costs.

2. The flat wire motor is small in size and uses less material under the same power, or with the same volume, the slot full rate is improved, and the power density is continuously improved. The full rate of round wire grooves is about 40%, and the full rate of flat wire grooves can be increased to about 70%. Since the cross section of the round wire is circular, there are some irregular structural gaps between the wires, while the gap of the flat wire is small and the slot full rate is high.

3. High Power Density Makes Vehicles More Powerful. The power of the motor is proportional to the copper content, the flat wire motor slot full rate is increased, the copper wire filling amount increases by 20-30% under the same product volume, and the output power technology is expected to be improved by 20-30%, making the vehicle more dynamic.

4. The electromagnetic noise of the flat wire motor is low. The stress and rigidity of the motor conductors are large, which can make the armature have good rigidity, thereby suppressing the armature noise. Using a smaller slot size can effectively reduce the cogging torque and further reduce the electromagnetic noise of the motor.

5. The end of the flat wire motor is short, which saves copper and improves the efficiency of the motor. Due to technical problems, the ends of conventional round wire motors are usually long, otherwise the copper wires are easily damaged during processing. For flat wire motors, because the wires are all hard wires, the ends can be made smaller during processing, saving copper, and improving motor efficiency. In addition, the flat wire motor adopts a more advanced winding method, which brings the end of the flat wire motor easier to cut. Compared with the round wire motor, the size of the end of the flat wire motor is reduced by 15-20%, and the space is further reduced. Miniaturization and weight reduction of the motor.

6. The flat wire motor has good heat dissipation and improves high temperature power. The internal clearance of the flat wire motor becomes smaller, the heat dissipation performance is good, and the temperature rise is 10% lower than that of the round wire motor. Because the flat wire is in closer contact with the round wire and the heat dissipation is improved, the study found that the thermal conductivity between the windings under the high slot full rate is 150% of the low slot full rate. The contact between the winding and the core slot is better, the heat conduction is better, and the thermal conduction capacity in the axial direction is 100 times that in the radial direction. The lower the temperature rise, the better the acceleration performance of the car.

The reason why flat wire motor companies will become the future trend is determined by the development level of electric drive systems for new energy vehicles. The characteristics of miniaturization, integration, and high power density are the evolution directions of electric drive systems for new energy vehicles. After all, bulky, heavy and weak drive systems are not welcome in the new energy vehicle market, and flat wire motors conform to the development trend of new energy vehicles.

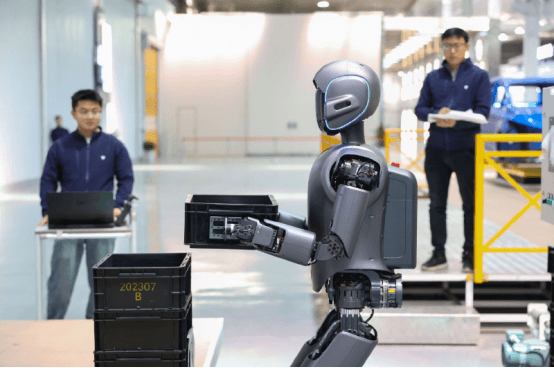

HONEST focuses on the hairpin (flat wire) motor manufacture for a certain time and got a good result on it. If you have some question about the hairpin motor production line, we are glad to reply.

Previous page

Related News