News Center

How to Make the Enamel Insulated Wire More Neatly Arranged During Motor Assembly?

Published on.

2024-11-26 11:46

Source

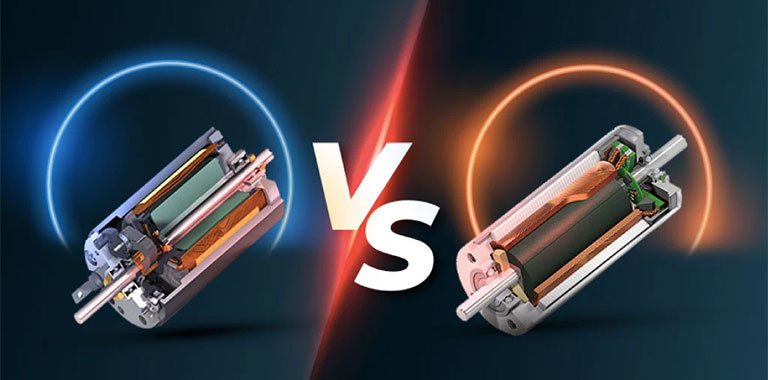

In the motor manufacturing process, the neatness of the enamel-insulated wire arrangement is crucial to the performance and reliability of the motor. As a professional supplier of motor intelligent equipment solutions, we have deeply analyzed the reasons for the uneven arrangement of the enamel insulated wire and provided a series of targeted solutions to ensure that the enameled wire of the motor is arranged more neatly.

The reasons for the uneven arrangement of enamel insulated wire include:

1. Differences in enamel insulated wire quality: If the enameled wire itself has quality problems, such as uneven paint layer, insufficient strength or uneven thickness, these may affect the neatness of the wire arrangement.

2. Winding speed: Too fast a speed during the winding process may cause deviations in the arrangement of the wires, especially when the wire diameter is large. Too fast a speed is more likely to cause uneven multi-layer coils.

3. Improper tension control: Too little tension will cause the winding to be loose and loose; too much tension will easily cause wire breakage and damage, thus affecting the arrangement of the enamel-insulated wire.

4. Wire arrangement device and mold device: If the matching accuracy of the wire arrangement device and the mold device is not enough, it may also cause deviations in the arrangement of the enamel insulated wire.

5. Improper operation: During the winding process, if the operation is improper, such as the winding speed is too fast or the winding angle is not vertical, it may cause the enameled wire to be arranged unevenly.

In view of the reasons why the enameled wire is not arranged neatly, we provide the following solutions:

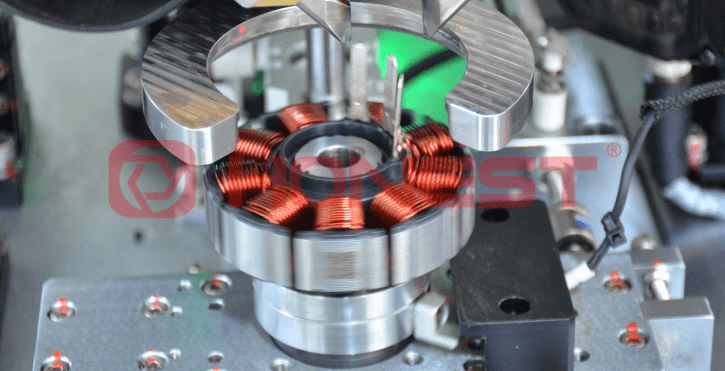

1. Accurate tension control: Use a high-precision tensioner to ensure that the enameled wire maintains appropriate tension during the winding process to avoid uneven arrangement caused by being too loose or too tight.

2. Optimize winding machine parameters: By accurately adjusting the speed parameters of the winding machine, ensure that while maintaining production efficiency, the arrangement deviation of the wire due to excessive speed is avoided.

3. Improve the wire arrangement & mold device: Use high-precision wire arrangement device and mold device to ensure that the arrangement position of the wire can be accurately controlled during the winding process.

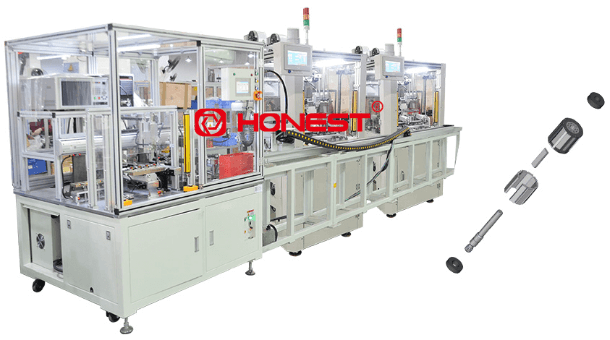

By implementing the above measures, the alignment of motor enameled wires during production can be significantly improved, thereby improving the performance and reliability of the motor. As a professional supplier of motor intelligent equipment solutions, we provide customized solutions for different customers, covering assembly line planning and design, efficient production line design, advanced assembly technology, intelligent control systems, etc., to meet the personalized needs of customers. In the future, we will continue to be committed to technological innovation and service optimization to provide customers with higher quality motor winding assembly solutions. HONEST Automation believes that through our continuous efforts and the support and cooperation of our customers, we will jointly promote the manufacturing industry to achieve easier and more efficient production.

Previous page

Related News

2024-11-07