News Center

Motor Stator Needle Winding: Say Goodbye to Inefficient Winding and Wind Easily

Published on.

2025-02-14 09:42

Source

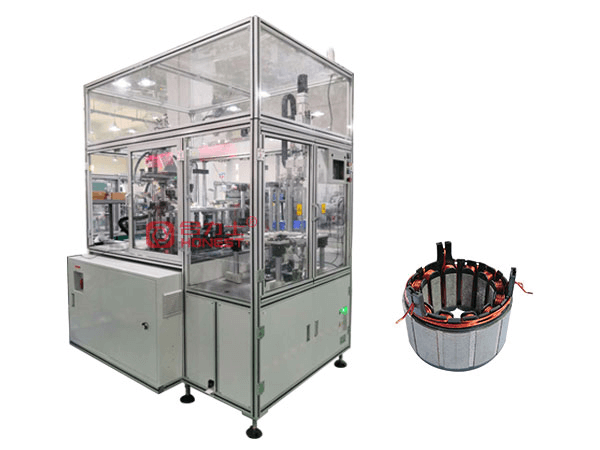

In the field of motor manufacturing, the stator is the core component of the motor, and its manufacturing quality and efficiency are directly related to the overall performance and production cost of the motor. However, in traditional stator winding, there are usually many complex winding tasks, such as multi-layer winding, winding of complex slots, high-precision winding requirements, etc. In the face of these challenges, stator needle winding machine are also constantly upgraded to actively respond to complex winding tasks. The needle-shaped tool can accurately wind the wire into the slot of the stator, and it has the characteristics of high precision and high efficiency, which can greatly improve the quality and production efficiency of stator manufacturing.

What are the Production Difficulties of the Winding Process:

① Poor winding flexibility: Under the traditional winding method, when it is necessary to produce stators with different outer diameters, heights or slot numbers, the debugging process of the equipment is complicated and time-consuming.

② Insufficient winding accuracy: During the winding process, the shape, size and position of the coil are difficult to accurately control, and problems such as coil deformation, short circuit or open circuit are prone to occur.

③ Low winding efficiency: The traditional manual winding method is extremely inefficient. Manual wire arrangement and calculation of the number of winding turns are required, which is not only labor-intensive but also prone to errors.

④ Complex multi-phase winding switching: Traditional single-needle winding machines require multiple winding operations, each phase wire is wound separately, and it takes a long time to switch winding, resulting in low production efficiency.

⑤ Difficulty in winding multi-wire slots: For stators with complex slots and multi-pole structures, traditional processes are difficult to achieve precise winding.

In the face of many difficulties in the winding process, the stator needle winding machine has been continuously upgraded and innovated. With its high flexibility, high-precision control capabilities and efficient automation performance, it has become an ideal choice in the motor manufacturing field. The needle winding machine can not only meet the diverse production needs, but also significantly improve production efficiency and product quality, bringing significant competitive advantages to enterprises. The specific advantages and solutions are as follows:

- High flexibility to meet diverse production needs: Through simple programming and parameter adjustment, different winding tasks can be quickly switched, greatly improving production flexibility and efficiency. This high flexibility enables enterprises to complete the winding of multiple products on one device, reducing equipment investment and production costs.

- High-precision control to ensure winding quality and performance: The equipment is equipped with advanced servo control systems and high-precision sensors, which can achieve precise control of the winding process. It can accurately control the needle's movement trajectory, speed and tension according to preset parameters to ensure that each circle of wire is evenly and tightly wound in the stator slot. It can also reduce defects that may occur during the winding process, such as coil deformation, short circuit or open circuit.

- Efficient automation, improved production efficiency and stability: Through automated control, the needle winding machine can achieve full-process automation from loading, winding to unloading. This automation not only reduces manual intervention and the risk of human error but also greatly improves production efficiency. The winding speed can usually reach hundreds of revolutions per minute, or even higher, and it can also achieve multiple parts winding at the same time.

With the increasingly fierce competition in the motor manufacturing industry, the stator needle winding machine provides efficient, accurate and flexible production solutions for motor manufacturers with its excellent performance characteristics. It can not only help companies optimize production processes and improve product quality but also reduce production costs and enhance the company's market competitiveness. For companies that are still troubled by the complexity and inefficiency of the winding process, the introduction of the needle winding machine is undoubtedly an important step towards efficient production. It will bring a new production experience to the company, easily solve the winding problem, and open a new chapter of efficient production.

Related News