News Center

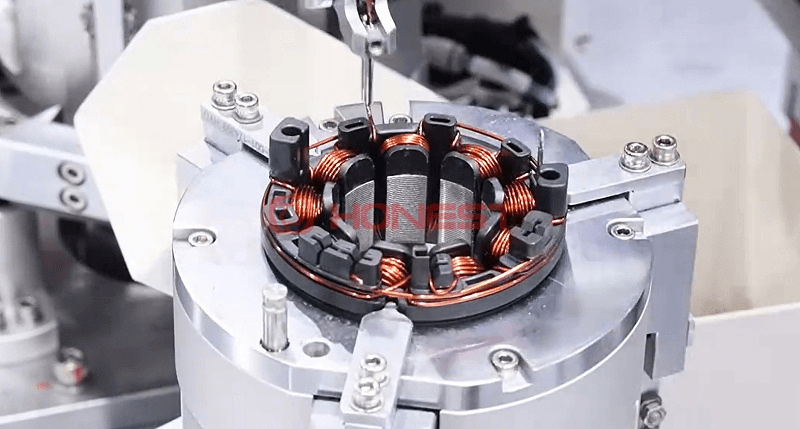

Segmented Stator Winding Machine: Boost Efficiency for Auto & Motor Makers

Published on.

2025-02-20 15:03

Source

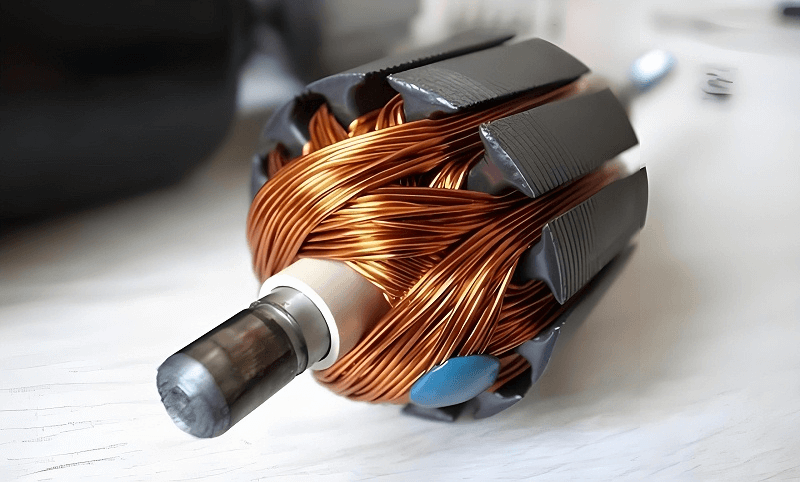

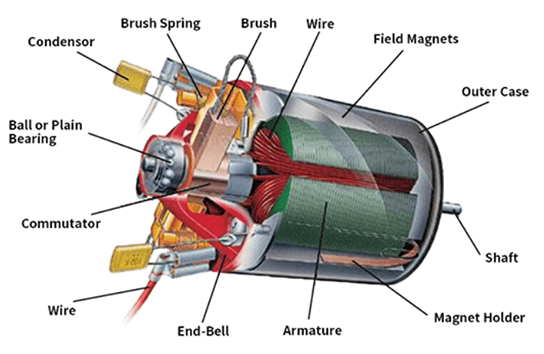

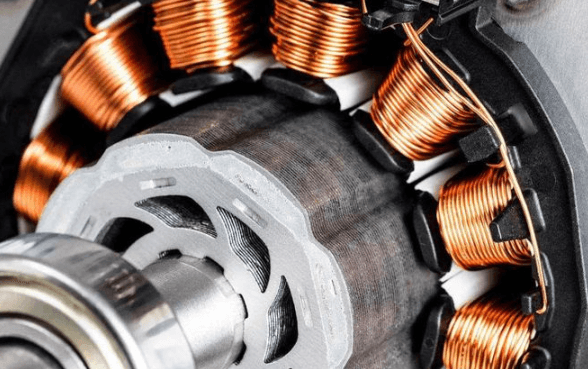

The traditional stator winding process requires that the copper wire be wound on the complete stator core at one time. This is not only complicated, time-consuming and labor-intensive, but also prone to problems such as uneven winding and insulation layer damage, which directly affect the performance and reliability of the motor. What's more serious is that once an error occurs during the winding process, it is extremely difficult to repair, and may even cause the entire stator to be scrapped, resulting in high material waste and increased production costs. For automobile and motor manufacturers that pursue high-efficiency and high-quality production, this traditional process not only slows down the production pace but also increases quality risks, becoming a key bottleneck restricting capacity expansion and cost optimization.

The segmented stator winding divides the stator into multiple independent modules. This "breaking the whole into parts" approach not only simplifies the winding process but also brings many advantages:

(1) More convenient winding: The stator module after segmentation is smaller in size, lighter in weight, and more flexible in operation, which greatly reduces the difficulty and intensity of manual operation.

(2) Higher precision: Segmented winding can achieve more accurate wire diameter control and wire density, effectively improving the consistency and stability of winding.

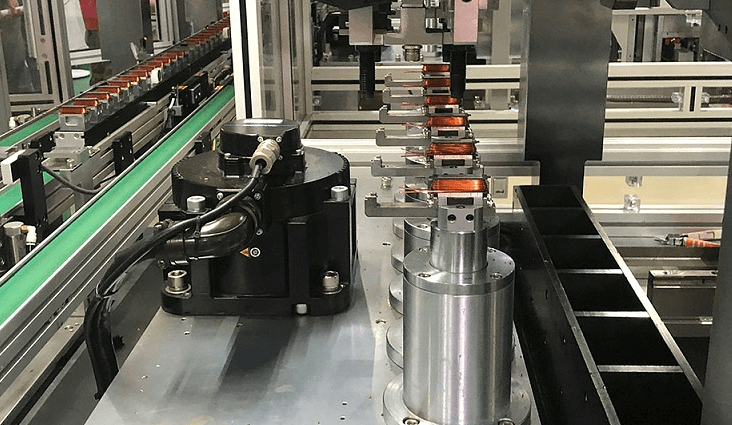

(3) Higher efficiency: Multiple modules can be wound at the same time, significantly shortening the production cycle and improving production efficiency.

(4) Consistency and stability: Accurate winding control ensures consistent winding quality for each module and improves product qualification rate.

(5) Reduced production costs: On the one hand, automated winding reduces labor costs; on the other hand, the efficient winding process also saves time costs. In addition, accurate winding can also reduce material waste and further reduce production costs.

Of course, the traditional stator winding method still has its unique advantages in certain specific scenarios. For example, for stators of simple shapes and sizes, its operational stability and maturity are relatively high. But in general, the block stator winding technology is more suitable for the complex and changeable modern industrial production needs.

How to Choose a Suitable Segmented Stator Winding Machine?

Choosing a suitable segmented stator winding machine requires comprehensive consideration from multiple aspects.

(1) Select the appropriate winding machine model and power according to production requirements (such as the outer diameter, inner diameter, stacking thickness, wire diameter, etc. of the stator) to ensure that the equipment can meet the company's production scale and product requirements.

(2) According to the production requirements of the product, the accuracy and degree of automation of the equipment must be selected. Winding machines with high accuracy and high automation levels can significantly improve winding quality and production efficiency.

(3) The stability and after-sales service of the equipment are also important reference factors. Choosing a supplier that provides comprehensive after-sales service and technical support can effectively reduce the risk of equipment use and ensure the smooth progress of the production process.

Due to its modular design and efficient and precise winding process, the segmented stator winding machine has become an indispensable production equipment in the motor manufacturing industry. It not only improves the winding accuracy, production efficiency and product consistency but also significantly reduces production costs, perfectly meeting the complex and ever-changing needs of modern industrial production. As a solution provider for intelligent motor equipment, HONEST Automation started with independent research and development of customized winding machines. With years of technological accumulation and innovation, it not only provides high-performance and high-quality winding equipment to the global market but also can perform non-standard customization according to the diverse needs of customers to meet the requirements of different application scenarios. In addition, we also provide customers with one-stop services from equipment research and development and selection to after-sales maintenance, to help the intelligent and digital development of the motor manufacturing industry.

Related News

2025-01-21