News Center

Segmented Stator Winding Machine: 5 Key Elements Precisely Aligned with Production Needs

Published on.

2025-05-26 16:08

Source

In modern manufacturing, segmented stator winding machines serve as essential production equipment, widely used in the manufacturing of motors, transformers, inductors, and other products. However, selecting the right type of segmented winding machine is crucial for improving production efficiency, ensuring product quality, and reducing manufacturing costs. This article provides a detailed overview of segmented stator winding machine types, production requirements, how to match machine types to specific needs, and key considerations for equipment selection — all aimed at helping enterprises make informed decisions in actual production environments.

1. Classification by Level of Automation

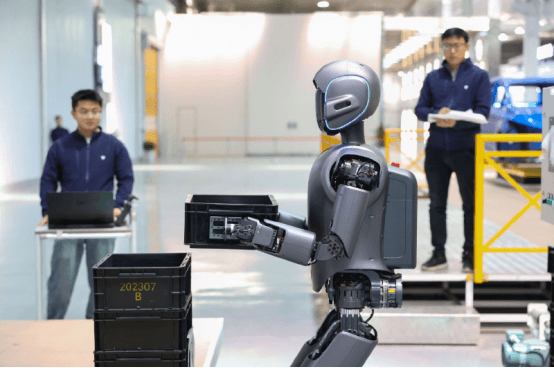

Fully Automatic Segmented Winding Machine

It features full automation throughout the entire production process, from loading, winding, and counting to unloading the finished products. Its advantages include high production efficiency, long-term stable operation, and excellent product consistency, making it ideal for large-scale and continuous production tasks.

Semi-Automatic Segmented Winding Machine

Requires manual assistance for certain operations, such as wire feeding and winding parameter adjustments. It is more suitable for small to medium-scale production tasks or production scenarios where product models change frequently.

2. Classification by Winding Method

Synchronous Winding: Multiple coils are wound simultaneously. This method offers high production efficiency, enabling the completion of a large number of coils in a short period. However, the equipment structure is relatively complex, and it demands higher quality and performance of the wire material.

Sequential Winding: Coils are wound one after another. The equipment structure is relatively simple, making it easy to maintain and operate. This winding method is suitable for small-batch, multi-variety production tasks and can flexibly accommodate the winding requirements of different products.

3. Classification by Applicable Wire Type

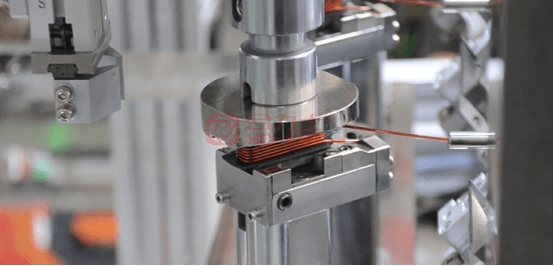

Segmented Winding Machines Suitable for Enamelled Wire: Enameled wire has good insulation and conductivity, and is commonly used as winding wire in motors, transformers and other products. The block winding machine suitable for enameled wire is designed with full consideration of the characteristics of enameled wire.

Segmented Winding Machines Suitable for Silicon Steel Wire: Silicon steel wire features high hardness and strength but is prone to deformation. To address these characteristics, segmented winding machines designed for silicon steel wire are equipped with motors that provide increased torque and optimized wire guiding devices. This design ensures that the silicon steel wire can smoothly pass through the guiding path during the winding process without issues such as wire jams or breaks due to insufficient torque. At the same time, it guarantees that the wound coils have a regular shape, meeting the product’s quality requirements.

4. Coil Specifications and Parameters

Coil Size: Different coil sizes impose varying requirements on the winding range and fixture design of segmented winding machines. For large coils, the machine must provide sufficient winding space and strong clamping force to ensure that the coil does not shift or deform during the winding process.

Number of Turns and Coils: The number of turns and coils directly affects the counting accuracy and winding speed of the segmented winding machine. A high-precision counting system ensures the exact number of turns, preventing quality issues caused by turn count errors. Additionally, the winding speed of the machine must be properly adjusted according to the required number of turns and coils.

Wire Diameter and Wire Type: The winding machine must have precise tension control for fine-diameter enameled wire to prevent wire breakage or irregular winding caused by uneven tension during the winding process. For harder silicon steel wire, the segmented winding machine’s wire guiding device must have excellent wear resistance and guiding performance to ensure the wire can smoothly pass through the guiding path during winding.

5. Production Process and Quality Requirements

Winding Tension: Proper winding tension ensures coils are tight and uniform, enhancing both the electrical performance and mechanical strength of the coils. Segmented winding machines need to be equipped with advanced tension control systems capable of precisely adjusting the winding tension according to the requirements of different wire types and coil specifications.

Coil Shape and Consistency: When production processes demand high consistency in coil shape, segmented winding machines must be equipped with high-precision winding shafts and guiding devices. High-precision winding shafts ensure concentricity and roundness of the coil during the winding process, while guiding devices help evenly distribute the wire on the winding mold, thus guaranteeing consistent coil shapes.

Insulation Processing: Some segmented winding machines are equipped with automatic insulation material winding functions, allowing insulation to be applied simultaneously during the winding process, thereby improving production efficiency. Additionally, the machine’s structural design must consider subsequent varnishing processes to ensure that the coils can be thoroughly impregnated with insulating varnish, enhancing the coil’s insulation performance.

In summary, selecting the appropriate type of segmented winding machine based on production needs is a comprehensive decision-making process. Enterprises must thoroughly understand the characteristics of different segmented winding types and identify key factors of their own production requirements during the initial selection phase. Additionally, considerations such as equipment maintenance before and after purchase, cost, and after-sales service should be taken into account. Through a well-informed selection process, companies can improve production efficiency, ensure product quality, reduce manufacturing costs, and thereby gain a competitive advantage in the fierce market environment.

HONEST Automation, as a professional supplier of intelligent motor equipment solutions, boasts advanced technology and extensive experience and offers complete turnkey solutions. Its segmented winding machines feature strong adaptability in winding methods and support automated upgrades such as insulation paper bonding and glue dispensing. At the same time, they improve slot fill rates, comprehensively meeting customer requirements and helping enterprises enhance production efficiency, reduce costs, and improve product quality.

Related News